Presentation Transcripts

Latest Update : Nov.21, 2016

Back to Financial Results (FY3/2017)

Investor Meeting Presentation for 2Q FY 3/2017 held on November 2, 2016

- Cover

- Table of contents

- Financial Results

- Summary of Consolidated Business Results for 1H

- Summary of Consolidated Business Results for 2Q

- Net Sales

- Operating Income

- Machined Components Business

- Electronic Devices & Components Business

- Net Income

- S.G. & A. Expenses

- Inventories

- Capital Expenditure & Depreciation

- Net Interest-Bearing Debt/Free Cash Flow

- Forecast for Fiscal Year Ending March 31, 2017

- FOREX impact on Minebea

- Policy and Strategy

- 1. Evaluation of 1H (FY 3/2017) Results

- 2. Full-year forecast (FY 3/2017)

- 3. External ball bearing sales steadily growing

- 4. Motor business to bring in steady income mainly from in-vehicle applications

- 5. Beefing up growth for sensing devices

- 6. Aircraft parts to focus on investments to grow

- 7. Status and Future of HDD-related Business

- 8. Current status of LED Backlight business

- 9. Integrating with MITSUMI with eye to next fiscal year and onward

- 10. LED backlights to remain in operation next year

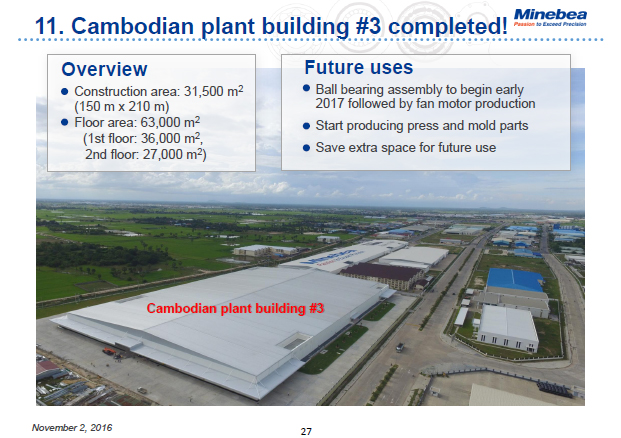

- 11. Cambodian plant building #3 completed!

- 12. New Sartorius MT&H Bengaluru plant

- 13. Plan to build new Slovakia plant

- 14. Marketing strategies to new heights

- 15. Business / capital alliance with Iwasaki Electric

- 16. Financial Strategies: Share buyback as an anti-dilution measure

- 17. Financial Strategies: dividend

- 18. Financial Strategies: M&A Strategies

- Forward-looking Statements (1)

- Forward-looking Statements (2)

Our Cambodian plant's third building was finally completed. Measuring 63,000 square meters, it's our largest factory. Since I believe factories are our best products, I hope to bring in major deals by showing this factory to lots of different customers. The first step is hand assembly of ball bearings. Since assembly of extremely tiny ball bearings cannot yet be automated, we will start off making them in Cambodia. We are getting things ready now with an aim to make 5 million units a month initially and will eventually increase the monthly production capacity to 10 million units. We will also start producing some of our fan motors in our Cambodian plant's Building No. 1 for shipment to customers in Southeast Asia.

The best news is that we are finally making parts in Cambodia. We had been planning to use the Cambodian plant for assembly operations due to its relatively high electricity bills. Now that we have solved the problem of high electricity costs, we will start producing press and mold parts there. For this reason, we made some last minute design changes to Building No. 3, such as creating a space with a reinforced floor that could fully withstand the weight of the manufacturing equipment for press and mold parts. We are looking to begin integrated production in Cambodia in the near future and expect to leverage the Cambodian plant in the location strategy of MITSUMI's manufacturing operations.

28page (total 37pages)

![]() You need Adobe Reader® to view these documents. Click on Adobe Reader icon on the left to download the software from the Adobe Systems website.

You need Adobe Reader® to view these documents. Click on Adobe Reader icon on the left to download the software from the Adobe Systems website.

It ends about main text.