2025

Sept.22, 2025

MINEBEA MITSUMI Inc.

MinebeaMitsumi's Specially Made Ruby Ball Bearing

Adopted for ŌTSUKA LŌTEC's Watch "No.9"

MinebeaMitsumi Inc. (head Office: Nagano Prefecture, Representative Director, Chairman & CEO: Yoshihisa Kainuma; hereinafter "MinebeaMitsumi") is pleased to announce that its specially made ruby ball bearings, along with the world's smallest ball bearings*1 have been adopted for the mechanical watch "No.9" by the Japanese watch brand, ŌTSUKA LŌTEC.

"No.9"

Ruby Ball Bearing

ŌTSUKA LŌTEC, a Japanese watch brand, was established by Jiro Katayama, a recipient of the Contemporary Master Craftsman Award*2 and winner of the Grand Prix in the "Challenge Watch Prize" Category (for watches priced at 3,000 Swiss Franc or less) at Le Grand Prix d'Horlogerie de Genève 2024.

Announced by ŌTSUKA LŌTEC on September 22, 2025, "No.9" is a watch model featuring modules as well as an own-brand movement meticulously created by Mr. Katayama from a base movement. Complex mechanisms like hour striking and tourbillon are incorporated into a 48 mm-length x 30 mm-width square case.

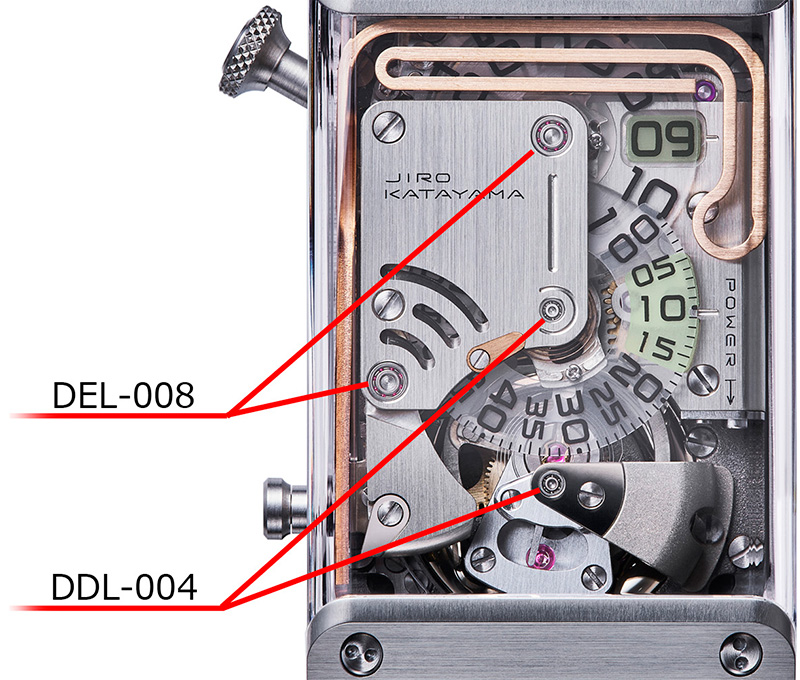

The watch uses a luminous block, which is placed on the right half of the dial, to illuminate the time from underneath. The upper and lower disks represent hour and minute, respectively. At the top of the hour, the hour striking goes into action and the hammer on the left half of the dial hits the pipeline-like gong. MinebeaMitsumi's ruby ball bearings, specially developed for "No.9" model, are used in the central shaft of the hour disk and hammer's movable shaft of the hour striking.

The world's smallest ball bearings and specially-made ruby ball bearings plays a vital role in supporting precise, smooth motion in the core part of the complex mechanisms, such as hour striking and tourbillon.

This ruby ball bearing is particularly an innovative component as it integrates ruby, a traditional component material for a watch with modern ultra-precision technologies. The sparkle of a ruby adds an artistic accent to the mechanism, and ruby's unique hardness and smoothness help minimize friction. Furthermore, the bearings remain durable across temperatures changes, ensuring long-term precision and reliability. The originality of "No.9" was realized through the idea to add new values to tradition and MinebeaMitsumi's technological capabilities allowing the idea to life.

- *1 Minebea's Bearing with 1.5 mm in Outer Diameter achieved a GUINNESS WORLD RECORDS™ title for the Smallest Commercially Available Steel ball bearing (Press release published on August 31, 2015)

- *2 Contemporary Master Craftsman Awards:

Award for Outstandingly Skilled Workers commended by the Ministry of Health, Labor, and Welfare since 1967.

About MinebeaMitsumi's Miniature Ball Bearing

MinebeaMitsumi's ball bearing, the company's original business and starting point, is driven by the ultra-precision technology cultivated over 70-year pursuit of excellence. The company internally encompasses a wide range of production aspects, from machining cutting tools, jig and tools, production facilities, environmental measures, and development of advanced machining technologies, to maintain the machining precision by controlling nanometer-scale machining diensions.

The manufacturing process from cutting to the final process of the specially made ruby ball bearing and the world's smallest ball bearing are manually manufactured by a limited number of the company's engineers.

This ultra-precision machining technologies and vertically integrated production system are one of MinebeaMitsumi's core competences.

MinebeaMitsumi's Karuizawa Plant

Manually assembling the ball bearing (at Karuizawa Head Office Plant)

| Size | Outer diameter: | 1.50 mm |

|---|---|---|

| Inner diameter: | 0.50 mm | |

| Thickness: | 0.65 mm | |

| Production Location: | Japan (Karuizawa Head Office Plant) | |

| Size | Outer diameter: | 2.50 mm |

|---|---|---|

| Inner diameter: | 1.00 mm | |

| Thickness: | 0.70 mm | |

| Production Location: | Japan (Karuizawa Head Office Plant) | |

Newly Developed Special Ruby Ball Bearing (One tick mark represents 0.5 mm)

Overview of ŌTSUKA LŌTEC's "No.9"

| Functions | Jumping hours/Rewinding minutes/Tourbillon/Hour-striking/Power reserve indicator |

|---|---|

| Winding | Manual-winding |

| Movement | In-house Cal. SSGT (Manual-winding, 30 jewels+5 ball bearings, 18,000 vph (3Hz), Power reserve: approximately 40 hours, Free sprung balance) |

| Case size | Diameter 48 mm, Width 30 mm |

| Case thickness | Maximum thickness 13 mm |

| Material | Sapphire crystal + Stainless steel (316 L) |

| Case finishing | Hair-line finish |

| Case-back | Solid back |

| Water resistance | 3 ATM |

| Strap material | Calfskin |

| Lug widths | 26 mm |

| Details of ball bearing | DEL-008 (two units)/DDL-004 (two units) DEL-008 is specially made ruby ball bearing. (Custom-made special bearing for ŌTSUKA LŌTEC's mechanical watch "No.9") |

| Country of origin | Japan |

| Price including tax | 17,600,000 yen (1-year warranty) |

About ŌTSUKA LŌTEC

ŌTSUKA LŌTEC is the Japanese watch brand founded in 2012 by Jiro Katayama, a recipient of the Contemporary Master Craftsman Award. All of its watches are meticulously crafted in-house under the direction of Mr. Katayama. His career began as a car and product designer, but after winning a bench lathe through an online auction in 2008, he shifted to watchmaking and selling his watches in 2012. His creation "No.6" was awarded the Le Grand Prix d'Horlogerie de Genève 2024 in the "Challenge Watch Prize" category (for watches priced at 3,000 Swiss Francs or less).

About MinebeaMitsumi

MinebeaMitsumi is an INTEGRATED* precision components manufacturer that develops, manufactures, and sells a wide range of mechanical and electronic components, leveraging its core technologies in ultra-precision machining. The company holds the world's No.1 market share** in miniature & small-diameter ball bearings, which ensures smooth mechanical rotation, as well as single-cell protection ICs for lithium ion batteries. Its advanced technologies also extend to key components such as semiconductors, motors, and sensors.

MinebeaMitsumi's ultra-precision technologies are utilized across a broad applications—from household appliances such as air conditioners, vacuum cleaners, and hair dryers, to IT devices like gaming consoles, smartphones, and PCs; as well as in automobiles, aerospace and aviation products, and medical equipment. While often unseen, MinebeaMitsumi's components play a crucial role in supporting everyday life behind the scenes.

* This term was adopted with the intended meaning of "combining" rather than "summing up" resources. MinebeaMitsumi Group is committed to creating new values through synergy effects.

- ** According to MinebeaMitsumi

| Media Inquiries | Corporate Communications Office and Investor Relations Office, MinebeaMitsumi Inc. Phone: +81-(0)3-6758-6703 Fax: +81-(0)3-6758-6718 E-mail: koffice@minebeamitsumi.com |

|---|---|

| Sales Inquiry for Bearing | Bearing Sales Management, MinebeaMitsumi Inc. Phone: +81-(0)3-6758-6772 |

Product information, contact and other context are subject to change without prior notice.