Initiatives for Effective Use of Resources Back Number (2012)

Back to Latest Initiatives for Effective Use of Resources

Basic Approach

The Minebea Group recognizes that there are limits to the availability of resources used in its products, which include metals, plastics, and other raw materials, along with oil, natural gas, and other energy sources. Additionally, with regard to rare earth elements indispensible to the manufacture of electronics, both the availability and the number of countries exporting the material are limited, making it more susceptible to export restrictions.

We believe that the effective use of resources is critical to the continuation of our business activities, and to that end we are taking various management measures.

Results of FY2011 Initiatives

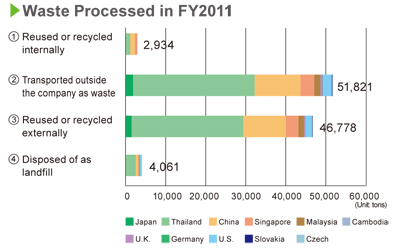

In FY2011, principal raw materials used by Minebea Group as a whole included approximately 71,400 tons of steel and 6,800 tons of resin, up approximately 8% over the preceding term. The amount of landfill waste generated by the Group's operations in FY2011 totaled 4,061 tons, about the same level as in FY2010 and falling short of our goal of under 4,000 tons.

In FY2011, principal raw materials used by Minebea Group as a whole included approximately 71,400 tons of steel and 6,800 tons of resin, up approximately 8% over the preceding term. The amount of landfill waste generated by the Group's operations in FY2011 totaled 4,061 tons, about the same level as in FY2010 and falling short of our goal of under 4,000 tons.

At our mass production plants in Thailand and China, we are recycling water inside the plants to the greatest extent possible as part of our aim for zero external wastewater emissions. In FY2011, the Ayutthaya Plant in Thailand also began implementing the zero emissions system, helping the Group reduce its wastewater emissions by 235,000 tons.

Initiatives at Offices

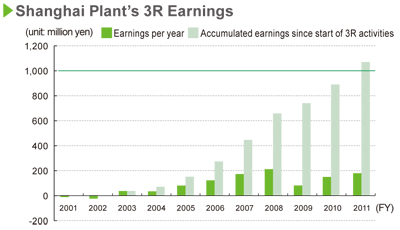

Accumulated Earnings of 3R Activities Surpass 1 Billion Yen (Shanghai Plant)

The Shanghai Plant launched a Reduce/Reuse/Recycle (3R) Committee in 2003 to effectively reuse and reduce its waste. In the first year of the program's operation, the plant incurred costs to dispose of most of its waste. By separating the waste, however, the plant was able to sell part of it. In the nine years since the program began, the plant has generated earnings of more than 1 billion yen from the sale of its waste.

The Shanghai Plant launched a Reduce/Reuse/Recycle (3R) Committee in 2003 to effectively reuse and reduce its waste. In the first year of the program's operation, the plant incurred costs to dispose of most of its waste. By separating the waste, however, the plant was able to sell part of it. In the nine years since the program began, the plant has generated earnings of more than 1 billion yen from the sale of its waste.

Conversion of Raw Kitchen Waste into Biogas (Thailand)

Biogas generation equipment

Our Bang Pa-in and Lop Buri Plants constructed biogas generation plants in FY2011 as part of the Thai Ministry of Energy's plan to promote the recycling of raw waste into biogas energy. The biogas generated is being used in place of LP gas in the plant cafeteria.

Use of biogas helps reduce the consumption of fossil fuels, and since the energy is generated through natural lifecycles, it has an extremely low environmental impact.

Utilization of Packaging Waste Material Such as Wooden Boxes (Thailand)

A sign, tables and chairs made from packaging waste products

The Bang Pa-in and Ayutthaya Plants recycle the wood from wooden packing boxes and other forms of packaging waste to create signboards, tables, shelves, desks, chairs and other useful objects that are used on the plant premises.

Future Issues and Goals

The Minebea Group is taking measures to reduce the amount of landfill waste it generates.

For FY2012, the Group is aiming to reduce landfill waste to under 4,000 tons, the same target as the previous year. We are currently researching the types of landfill waste being generated and the marketability of the waste, the first steps in our plan to greatly reduce the amount generated over the next several years.