Product-related Initiatives for the Environment Back Number (2016)

Back to Latest Product-related Initiatives for the Environment

Basic Approach

Since its products are utilized in many different kinds of end-products, the Minebea Group believes that it has an especially important role in providing parts that contribute to environmental consciousness throughout the product life cycle. This responsibility extends from ensuring that its parts are free of materials hazardous to the environment, to energy-efficiency, resource-efficiency, and long-life.

Group's Environmentally Conscious Products

The products that the Minebea Group produces and sells are environmentally conscious. This means that they satisfy various countries' environmental laws and customers' environmental requirements from the development and design stage as well as undergoing voluntary product chemical substance evaluations and product assessments.

Launching Mass Production and Sales of New Lighting Product, "SALIOT"

External view of SALIOT

The Minebea Group has developed the world's first* LED lighting enabling users to adjust the light distribution angle. "SALIOT" (Smart Adjustable Light for the Internet of Things) harnesses light guiding panels and plastic injection molding technologies developed for LED backlights. We began mass production and sales of this innovative product in July 2015.

SALIOT can adjust its light distribution angles from 10° to 30° by using a motor to control the distance between the light emitting diode and the lens. Leveraging wireless technologies, we added proprietary software enabling users to easily control the light distribution angle, brightness, and illumination position with a smartphone or tablet.

SALIOT can provide multiple light sources from a single illumination, making it ideal for such commercial complexes as large-scale shopping centers with high ceilings, car dealer showrooms, art and other types of museums, educational facilities, event spaces, hotels, and a wide variety of other venues. SALIOT helps to solve a number of issues posed by the lighting of large spaces, including the elimination of dangerous work involved with adjusting lights in high places, as well as improving energy efficiency through the use of LED lighting.

* Based on company’s research as of July 2015

Development of High Heat-resistant Ball Bearing Unit for Turbochargers

High heat-resistant ball bearing units for turbochargers

The Minebea Group has developed and begun manufacturing and selling a high heat-resistant ball bearing unit for turbochargers (air supply device to force air into the engine) which prevents burning of the unit's components. The balls are made of ceramics and the casings used to hold the balls are made of high heat-resistant materials to prevent the shaft bearing from expanding and burning.

Currently, automakers around the world are striving to improve the fuel efficiency of engines to make them more environmentally conscious. As one measure, automakers have been adopting smaller displacement engines and fitting them with air supply devices to boost output and thereby raise fuel efficiency.

We expect these trends to gain further momentum in Japan and Europe, where fuel efficiency regulations are tightening, and in North America, where large-sized gasoline cars are common.

Auxiliary Device for Small Machine Tools "Wavy Nozzle"

Exterior view of Minebea's "Wavy Nozzle" (in KICK mode operation)

The Minebea Group has developed an auxiliary device for small machine tools named "Wavy Nozzle" which removes machine dust and chips through swing jetting of coolants*. By spraying coolants while oscillating to the point of processing, machining dust and chips will be removed efficiently, thereby contributing to the realization of quality improvement and efficiency enhancement for precision component machining.

Minebea has successfully developed a device capable of efficiently removing machine dust and chips without employing a large-scale "high-pressure coolant system" that had been conventionally used in the market. As such, this product can be installed in small-sized machine tools (small CNC lathes and machining centers, etc.), with which a large-sized high-pressure coolant system could not be loaded up to date.

* Cutting fluids, or grinding fluids which produce a cooling or lubrication effect on the processing point in machine processing

LED Backlight Units for LCD Displays

Backlight Unit for LCD Panel

The Minebea Group develops, manufacturers, and sells LED (light-emitting diode) backlight units which illuminate smartphone and tablet computer LCD displays from the rear.

The LED is positioned on the edge of the device, and the light guide plate is critical to spreading LED light evenly over the display. We leveraged our proprietary design development and superior plastic injection molding processes used in precision metals molding to successfully develop light guide plates measuring 0.3 mm thick or less. The thinner light guide plates not only help to make the end products thinner, but help to reduce power consumption, weight and size compared with previous models.

High-performance VR Resolver (Rotation Angle Sensor)

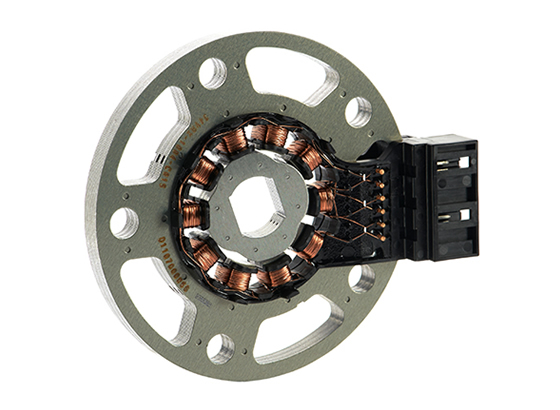

High-performance VR resolver

The Minebea Group has developed a high-performance VR resolver (rotation angle sensor), a critical component of drive motors used in next-generation eco cars, including electric vehicles (EVs), hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs). The Group is producing and delivering the component to automakers in and outside Japan.

The VR resolver is a vital angle sensor for accurately controlling the rotation of the drive motor. It is a key component that significantly affects power consumption and driving performance of eco cars.

Management of Environmental Impact Materials Included in Products

The Minebea Group has issued the Minebea Group Green Procurement Standard requiring suppliers to supply products (raw materials and parts) free of hazardous substances along with data and documentation verifying their products' safety. We also conduct our own verification tests of suppliers' products using XRF (X-ray fluorescence spectrometers) to ensure the products are free of hazardous materials subject to RoHS regulations.

Management methods for chemical substances contained in products

- Note 1. (M)SDS ((Material) Safety Data Sheet):

A data sheet covering information required for safe handling of chemical substances (ingredients, characteristics, handling methods, and emergency coping methods). - Note 2. MSDSplus:

A data sheet recommended by the Joint Article Management Promotion Consortium (JAMP) to communicate basic information regarding chemical substances and compounds. Contains information not included in the (M)SDS that is required for management of toxic chemicals incorporated in products. - Note 3. AIS (Article Information Sheet):

A basic sheet recommended by JAMP for communicating information on toxic chemicals incorporated in product molds. Compiled based on (M)SDS, MSDSplus, etc. - Note 4. JGP File:

A standard format file stipulated for Green Procurement inspection by the Japan Green Procurement Survey Standardization Initiative (JGPSSI).

Future Goals and Issues

The Minebea Group will continue to accurately grasp the detailed needs of society in order to develop products that can contribute to safety, energy-efficiency and resource-efficiency.