Product-related Initiatives for the Environment Back Number (2011)

Back to Latest Product-related Initiatives for the Environment

Basic Approach

A majority of the products manufactured by the Minebea Group, such as bearings and motors, are components in products sold by our customers, and are not immediately visible. But precisely because our components are incorporated into such a wide variety of products, the Minebea Group believes it is important to offer products that are safe and free from harmful substances that might damage the environment, products that contribute to overall lifestyles by being energy- and resource-efficient as well as long-lasting.

Management of Environment-affecting Substances Incorporated in Products

The Minebea Group publishes the Minebea Group Green Procurement Standard and requests that suppliers provide products (raw materials and components) that are free from harmful substances, as well as data and documentation verifying their adherence to the standard. Furthermore, XRF (X-ray fluorescence spectrometers) are used in the Minebea Group's inspections of goods received to confirm that they do not contain any substances subject to the RoHS directive.

- Note 1. MSDS (Material Safety Data Sheet):A data sheet covering information required for safe handling of chemical substances (ingredients, characteristics, handling methods, emergency coping methods).

- Note 2. MSDSplus: A data sheet recommended by the Joint Article Management Promotion Consortium (JAMP) to communicate basic information regarding chemical substances and compounds. Contains information not included in the MSDS that is required for management of toxic substances incorporated in products.

- Note 3. AIS (Article Information Sheet): A basic sheet recommended by JAMP for communicating information on toxic substances incorporated in product molds. Compiled based on MSDS, MSDS Plus, etc.

- Note 4. JGP File: A standard format file stipulated for Green Procurement inspection by the Japan Green Procurement Survey Standardization Initiative (JGPSSI).

Fundamental Environmental Products

High-precision, High-quality Bearings

Ball bearings

Bearings are a fundamental industrial product that is indispensible for humanity. Bearings enable parts to move easily and rotate smoothly. They improve functioning, conserve energy, and enable devices to be made smaller and last longer.

The Minebea Group boasts the top share in two opposing segments of the market: that for miniature ball bearings with a outer diameter of 22mm or less, and that for rod ends and spherical bearings for the aviation industry.

However, for both types of bearings, users demand extremely high levels of precision and product quality. To enhance these attributes of our bearings even further, we must push the limits of technology for such product attributes as outer and inner race groove roundness, ball sphericity, and the material quality of constituent parts.

Using our proprietary production equipment, maintenance technology, production line architecture and other expertise embodying 60 years of accumulated knowhow, the Minebea Group produces all of its bearing components in-house, and has never stopped pursuing ever-higher precision and product quality.

These highly precise, quality bearings are incorporated in home appliances, telecommunications equipment, automobiles and other products that play an integral role in our daily lives, and their high precision, extended service life, resource- and energy-efficiency and other characteristics are contributing to the environment in all kinds of ways.

Products Contributing to Energy Conservation

AC-DC Converter Raises Current Conversion Efficiency to 94%

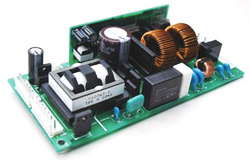

The new AC-DC converter that does not require heat sinks

A wide range of home appliances and office products, including televisions, air conditioners, PCs, and printers, operate by converting alternating (AC) mains current to direct current (DC) with an internal AC-DC converter. However, it is difficult to achieve 100% AC-DC conversion, and all of the current that cannot be converted to DC is radiated as heat.

Conventional AC-DC converters operating with an input voltage of 100 volts require two or three heat sinks affixed to the circuit board to dissipate heat into the air, because conversion efficiency is in the 87-90% range.

However, the new dual-boost LLC-type AC-DC converter developed by the Minebea Group achieves 93% efficiency with 100-volt input and 94% efficiency with 200-volt input without the need for heat sinks. Consequently, it was possible to reduce the height of the new converter board to 10 millimeters and reduce the number of parts required.

This newly developed AC-DC converter is expected to become a core energy-efficiency product for such applications as large flat-panel televisions and data center servers.

Brushless DC Motor: High-efficiency, Low Power Consumption, Long Service Life

Brushless DC motors

In FY2010, the Minebea Group began mass production of a brushless DC motor incorporating internal drive and control circuits.

Compared to DC motors that employ brushes to control the direction of current, the new DC motor consumes less power, is more efficient, and has a longer service life. The use of neodymium magnets and ball bearings developed by Minebea enhanced the motor's output characteristics. These motors are already being used in heliostat drive mechanisms for concentrated solar power systems, a potentially important next-generation source of electric power.

Furthermore, while DC motors using brushes have a power efficiency of 40-50%, brushless DC motors boast an efficiency of approximately 70%. Since it is estimated that more than half of all electricity consumed in machine operation is used to drive motors, demand for DC brushless motors is expected to increase in part due to their energy efficiency.

Products Contributing to Resource Conservation

Weather-resistant, Long-life, High-performance AC Fan Motors

AC fan motors

The Minebea Group has commercialized a series of weather-resistant, oil- and dust-proof AC fan motors with long service lives for products used in harsh environments, such as machine tools, and for such outdoor products as solar light generation systems and electric vehicle rechargers.

Enhancing weather resistance in all kinds of environments, this series saves user time and trouble required for maintenance while contributing to lower life cycle costs.

Future Issues and Goals

Going forward, the Minebea Group will continue to monitor the concrete needs of society, and work to develop products that are safe and contribute to energy- and resource-efficiency.

In addition, the Minebea Group will continue working to formulate standards for eco-friendly products (tentative name: Minebea Green Products).